BK-7 OPTICAL GLASS

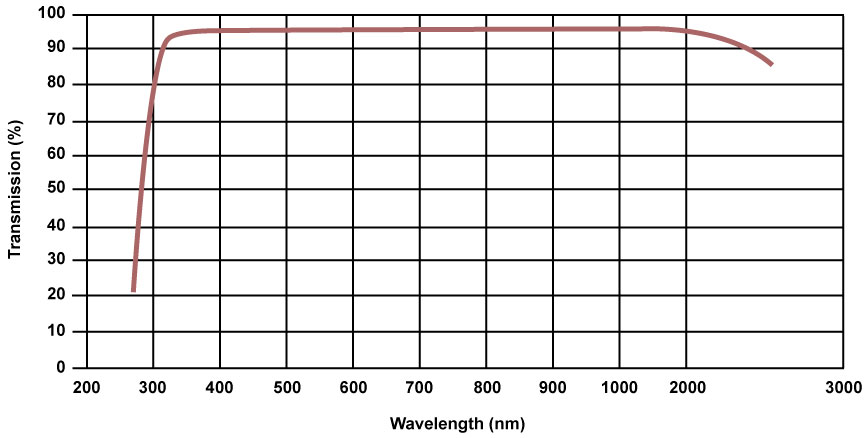

BK7 is a high quality optical glass that is used whenever the additional benefits of fused silica are not required. Since BK7 performs well in all chemical tests, and no additional or special handling is required, costs of manufacturing are reduced. It is a relatively hard material with extremely low bubble and inclusion content, while providing excellent transmittance through-out the visible and near infrared spectra and down to 350 nm in the ultraviolet.

For all standard optical glass components, or when optical glass is generically requested for custom elements, Glass Dynamics uses normal high quality BK7 optical glass.

OPTIMUM TRANSMISSION RANGE 350nm - 2.0µm

| Index of Refraction | |||

|---|---|---|---|

Wavelength, nm |

Fused Silica / Quartz |

BK7 |

Sapphire |

213.86 |

1.53427 |

- |

- |

230.21 |

1.52005 |

- |

- |

239.94 |

1.51337 |

- |

- |

265.20 |

1.50000 |

- |

1.83360 |

280.35 |

1.49403 |

- |

1.82427 |

302.15 |

1.48719 |

- |

1.81351 |

334.15 |

1.47976 |

- |

1.80184 |

346.62 |

1.47746 |

- |

1.79815 |

365.02 |

1.4752 |

1.53626 |

1.79358 |

404.66 |

1.46962 |

1.53024 |

1.78582 |

435.84 |

1.46669 |

1.52669 |

1.78120 |

546.706 |

1.4008 |

1.51872 |

1.77078 |

706.52 |

1.45516 |

1.51289 |

1.76303 |

852.11 |

1.45247 |

1.50981 |

1.75885 |

1013.98 |

1.45025 |

1.50731 |

1.75547 |

1529.52 |

1.4427 |

1.50094 |

1.74660 |

1970.09 |

1.43853 |

1.49500 |

1.73833 |

2325.42 |

1.43293 |

1.48929 |

1.73055 |

2325.42 |

1.43293 |

1.48929 |

1.73055 |

3243.90 |

1.41315 |

- |

1.70437 |

3507.00 |

1.40566 |

- |

1.69504 |

4954.00 |

- |

- |

1.62665 |

5577.00 |

- |

- |

1.58638 |

| Mechanical Properties of Optical Materials | ||||||||

|---|---|---|---|---|---|---|---|---|

Thermal |

Units |

Fused Quartz |

Fused Silica |

BK7 |

Pyrex® |

Sapphire |

||

Softening Point |

C° |

1180 |

1120 |

550 |

565 |

|||

Annealing Point |

C° |

1180 |

1120 |

550 |

565 |

|||

Strain Point |

C° |

1075 |

1025 |

624 |

515 |

|||

Maximum Temperature (Continuous) |

C° |

1000 |

950 |

350 |

230 |

1100 |

||

Maximum Temperature (Momentary) |

C° |

1300 |

1200 |

490 |

||||

Thermal Conductivity |

@ 20° C |

Cal cm cm2sec° C |

0.0033 |

0.0033 |

0.0026 |

0.0027 |

0.0065 |

|

@ 200° C |

0.0037 |

0.0037 |

||||||

@ 950° C |

0.0064 |

0.0064 |

||||||

Specific Heat |

0° -100°C |

cal g °C |

0.18 |

0.18 |

0.21 |

0.2 |

||

0° -900°C |

0.25 |

0.25 |

||||||

Coefficient of Thermal Expansion |

-50° -0° C |

cm cm °C |

2.7 x 10-7 |

2.7 x 10-7 |

||||

-50° -300° C |

5.9 x 10-7 |

5.9 x 10-7 |

86 x 10-7 |

33 x 10-7 |

||||

-50° -900° C |

4.8 x 10-7 |

4.8 x 10-7 |

90.3 x 10-7 |

|||||

| Strength/Hardness | ||||||

|---|---|---|---|---|---|---|

Moh Hardness |

5.5 - 6.5 |

5.5 - 6.5 |

5 |

9 |

||

Microhardness |

kg/cm2 |

9.4 x 104 |

9.4 x 104 |

|||

Knoop Hardness (100g load) |

kg/cm2 |

605 |

615 |

520 |

481 |

1525 - 2000 |

Density |

g/cm3 |

2.203 |

2.203 |

|||

Specific Gravity |

2.203 |

2.201 |

2.53 |

2.23 |

3.98 |

|

Compressive Strength |

kg/cm2 |

1.13 x 104 |

1.13 x 104 |

2.04 x 104 |

||

Tensile Strength |

kg/cm2 |

500 |

500 |

282 |

7000 |

|

Torsional Strength |

kg/cm2 |

300 |

300 |

1.5 x 106 |

||

Bending Strenght |

kg/cm2 |

680 |

680 |

|||

Young's Modulus |

kg/cm2 |

7.45 x 105 |

7.45 x 105 |

8.63 x 105 |

7 x 106 |

79 x 105 |

Shear Modulus |

kg/cm2 |

3.2 x 105 |

3.2 x 105 |

|||

Bulk Modulus |

kg/cm2 |

3.76 x 105 |

3.76 x 105 |

|||

Poisson's Ration |

0.17 |

0.17 |

0.208 |

0.2 |

0.02 |

|

| Electrical | |||||||

|---|---|---|---|---|---|---|---|

Dielectric Strength |

@ 20° C |

kv/cm |

250 - 400 |

250 - 400 |

480 |

||

@ 500° C |

150 - 200 |

150 - 200 |

|||||

Dielectric Constant |

(0-MHz) |

3.7 |

3.7 |

5.1 |

8.6 - 10.6 |

||

Dielectric Loss Tangent |

1 MHz |

1 x 10-4 |

1 x 10-4 |

8.6 x 10.6 |

|||

102 MHz |

1 x 10-4 |

1 x 10-4 |

|||||

3 x 104 MHz |

4 x 10-4 |

4 x 10-4 |

|||||

Resistivity |

@ 20° C |

Ω/cm |

1 x 1018 |

1 x 1018 |

|||

@ 600° C |

8 x 107 |

8 x 107 |

1 x 1011 |

||||

@ 1000° C |

1 x 106 |

1 x 106 |

1 x 106 |

1 x 1011 |

|||

Key Notes:

- All Properties measured at 20° C unless otherwise specified.

| Striae and Homogeneity | |||

|---|---|---|---|

Material Code |

Type |

Striae/MIL - G -174A |

Index Variation Δn(x10-6) |

S1 - UVA |

Fused Silica |

A |

6 |

S1 - UVB |

Fused Silica |

A |

10 |

A1 |

Fused Quartz or Fused Silica |

B |

10 |

G1 |

Fused Quartz or Fused Silica |

C - D |

20 |

I2 - IR |

Fused Quartz |

A |

4 |

BK7 |

Optical Glass |

A |

10 |

| Bubbles & Inclusions | ||||||

|---|---|---|---|---|---|---|

Up to 1.0" diameter |

From 1.0" to 2.0" Diameter |

From 2.0" to 3.0" Diameter |

||||

Material |

Maximum Diameter |

Maximum Quantity |

Maximum Diameter |

Maximum Quantity |

Maximum Diameter |

Maximum Quantity |

(Inches) |

Per Pc. |

(Inches) |

Per Pc. |

(Inches) |

Per Pc. |

|

S1 - UVA |

0.006 |

0 |

0.008 |

1 |

0.01 |

1 |

S1 - UVB |

0.008 |

1 |

0.015 |

1 |

0.015 |

1 |

A1 |

0.01 |

1 |

0.015 |

1 |

0.02 |

2 |

G1 |

0.03 |

3 |

0.04 |

3 |

0.06 |

3 |

I2 - IR |

0.01 |

3 |

0.015 |

3 |

0.02 |

3 |

BK7 |

0.006 |

0 |

0.006 |

0 |

0.01 |

1 |

Key Notes:

- These specifications are worst case conditions.

- Materials can be selected and guaranteed to customer requirements.

- Bubbles less than the maximum diameter count as a fraction of the allowed limit.

- Bubbles less than 0.004" are regarded as undetectable.

2012 © Glass Dynamics, LLC.

designed by kim@marketingtipsinprint.com